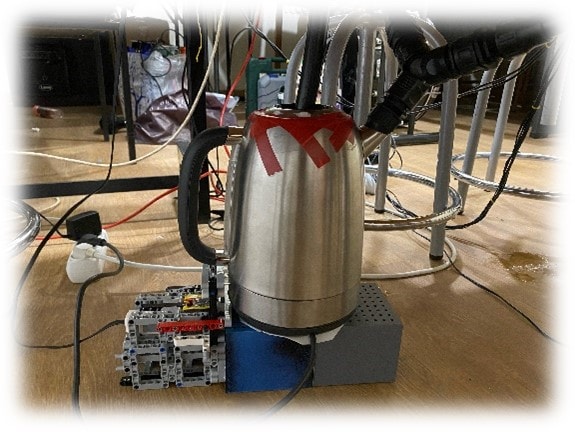

Project Airfield

Detailed Presentation

The reduced growth in the field of renewable sources of energy not only makes research hard, but it also makes the establishment of a new way to produce energy that is friendly to the environment challenging. For that reason, we decided that it would be better if we developed an already existent way of producing green energy. Wind energy.

The Basic Idea

“Airfield” is separated in 2 sectors: (a) in energy production through a flying windmill and (b) in consumption of that energy in a fully automated greenhouse. In the scope of this project, we do not store all the energy produced, we store the 25% of the energy that is more than enough for the operation of the greenhouse and the other 75% is sold to a grid.

Energy Production

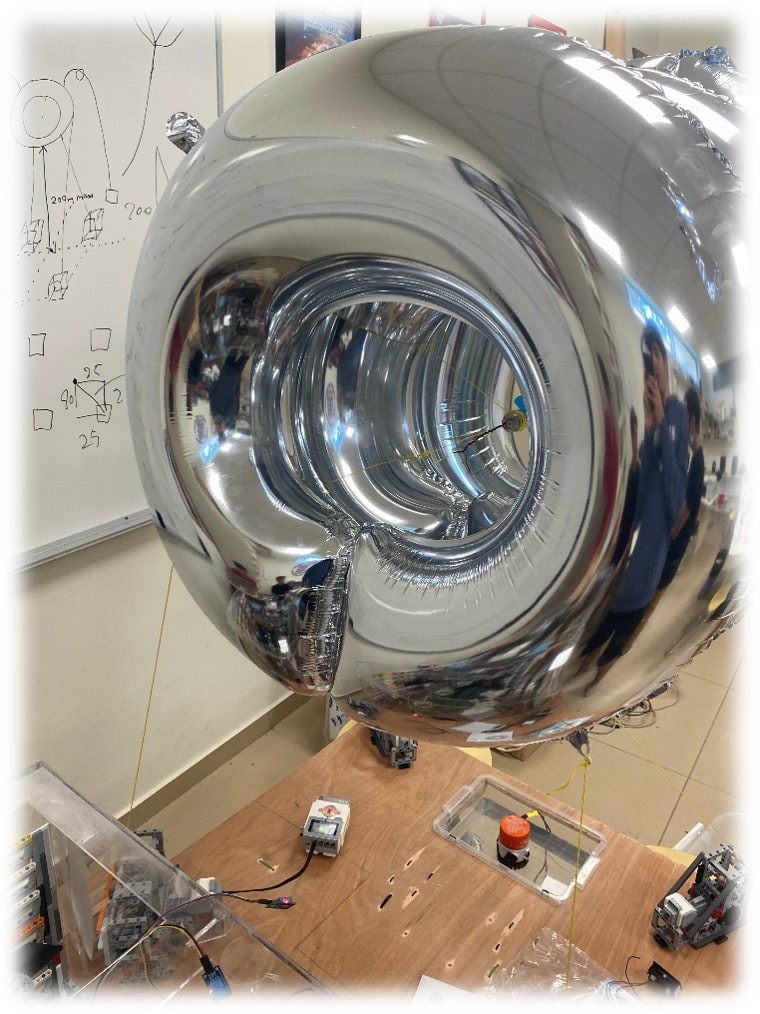

We all know that wind currents high above the ground are much stronger compared to those that operate relatively closer to the ground. The idea is to use a helium-filled, tube-shaped balloon to lift the turbine off the ground to a much higher height than conventional windmills. The airborne wind turbine will be held steady by making use of strong tethers which will also transfer the electricity generated to the ground. The prototype rises to a height of 350 ft from ground level, generating electricity and landing successfully if necessary. Some obvious advantages of this wind turbine include very little noise when operating, low land use, minimal maintenance of setup and the fact that it can be used anywhere since the currents are available at height regardless of the ground location. The electricity produced will be directly passed onto the network where it will be sold to energy suppliers and to operate the greenhouse.

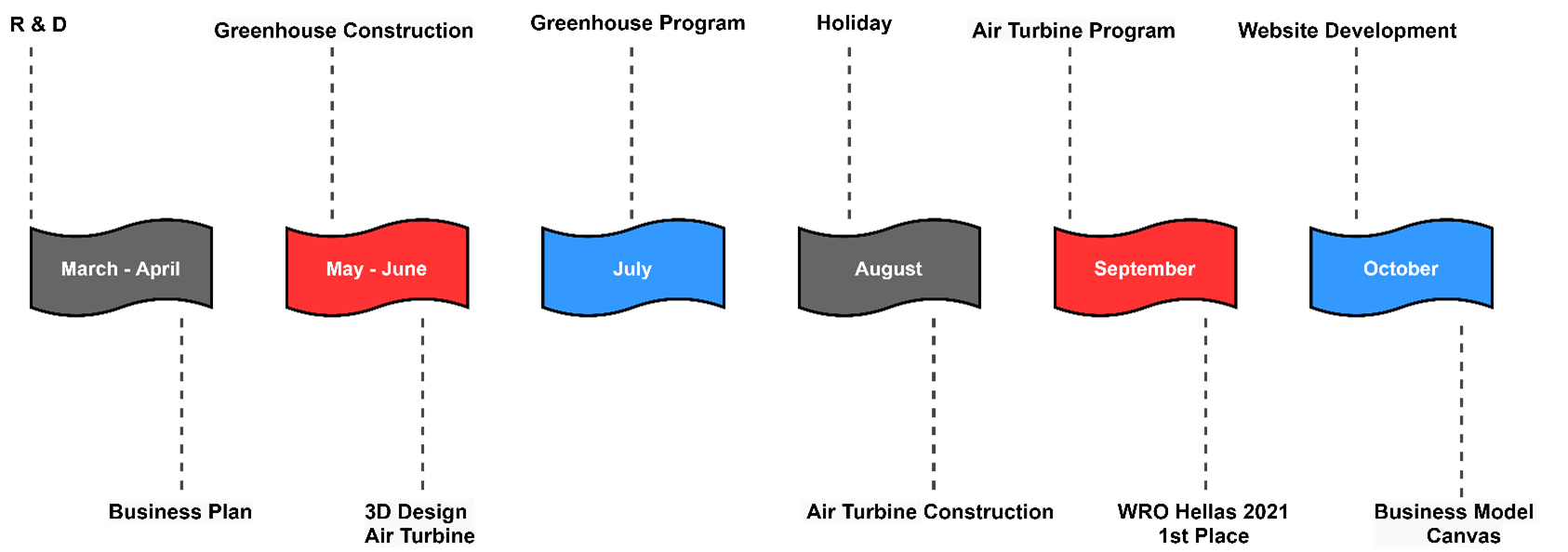

Energy Consumption

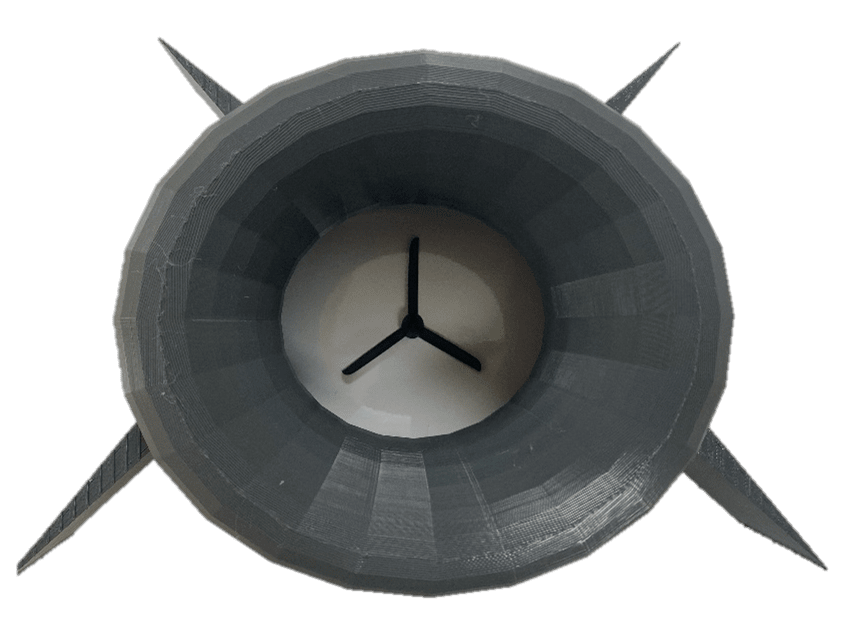

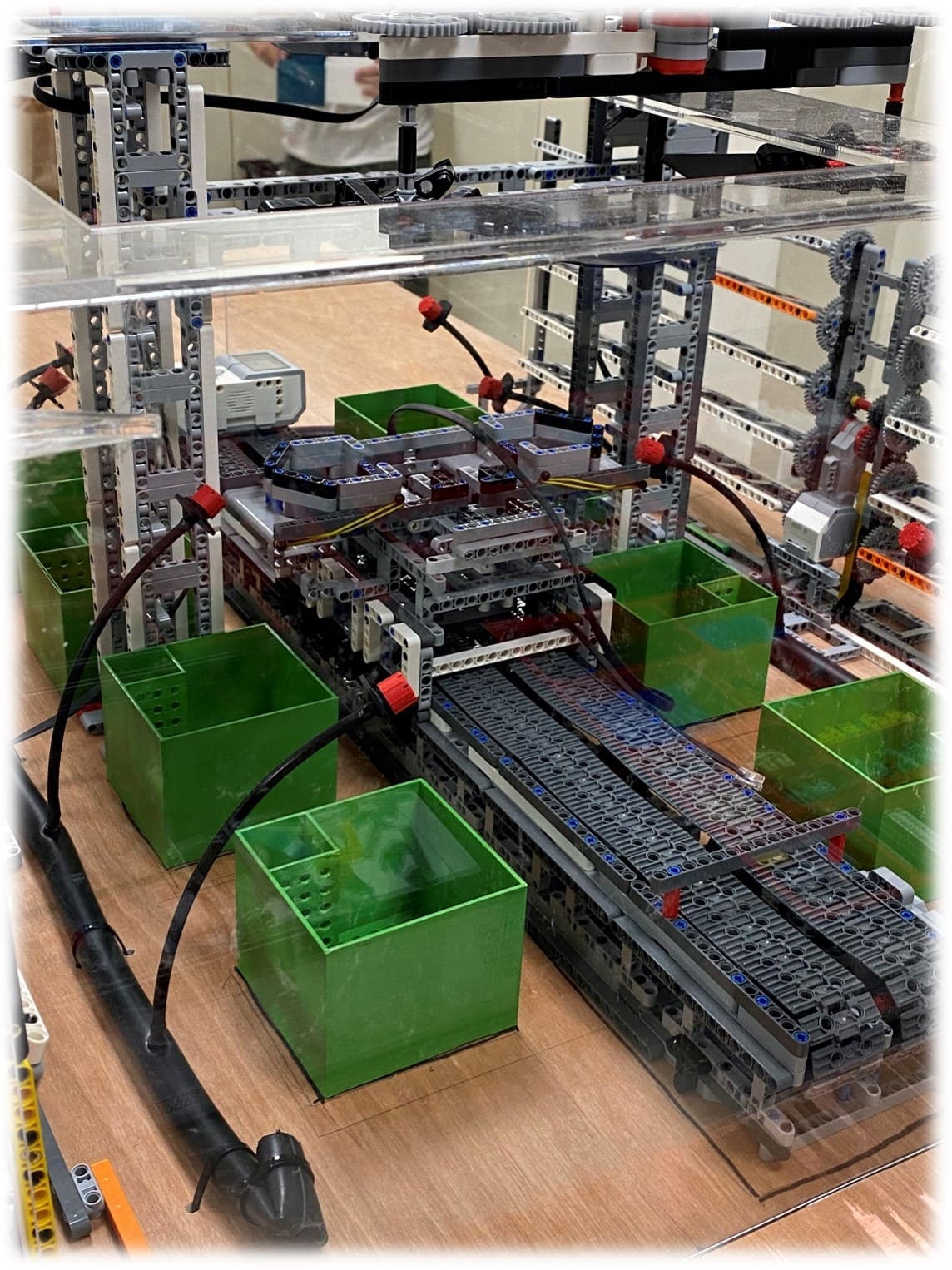

We use the 25% of energy produced to supply the automated greenhouse. The structural elements of the greenhouse are made of Plexiglas and the roof is covered by a special plastic cover. There are two windows on each large side of the greenhouse which permits the ambient air to get inside of the greenhouse when it is necessary. Inside the greenhouse 4 plants are placed on each side, the sides are 2 and they are separated by a conveyor belt. On the top of the belt, there is a robot whose responsibility is to check if the plants need to be fertilized or not. Under the greenhouse, there is a kettle which under normal conditions would be a boiler that would heat the water. The water would circulate in pipes in the greenhouse in order to raise the temperature. The hot air from the kettle is used to raise the temperature of the water. In case we want to lower the temperature, we operate the fans in the greenhouse. Finally, the plants are watered automatically. The frequency of the irrigation system operation depends on the species of the plants.

Top locations for the Project

After a careful study, we came to the conclusion that Airfield can harmonize perfectly with most lowland areas.

The Robot

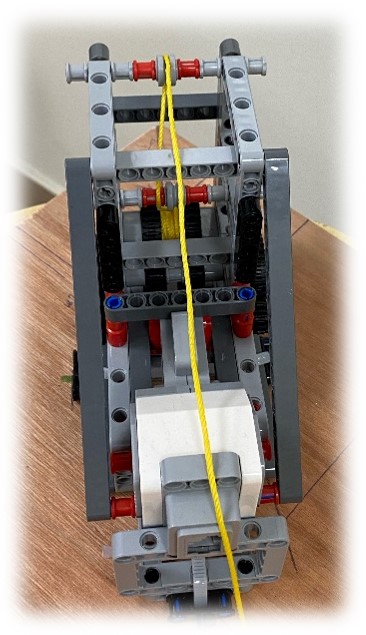

The robot

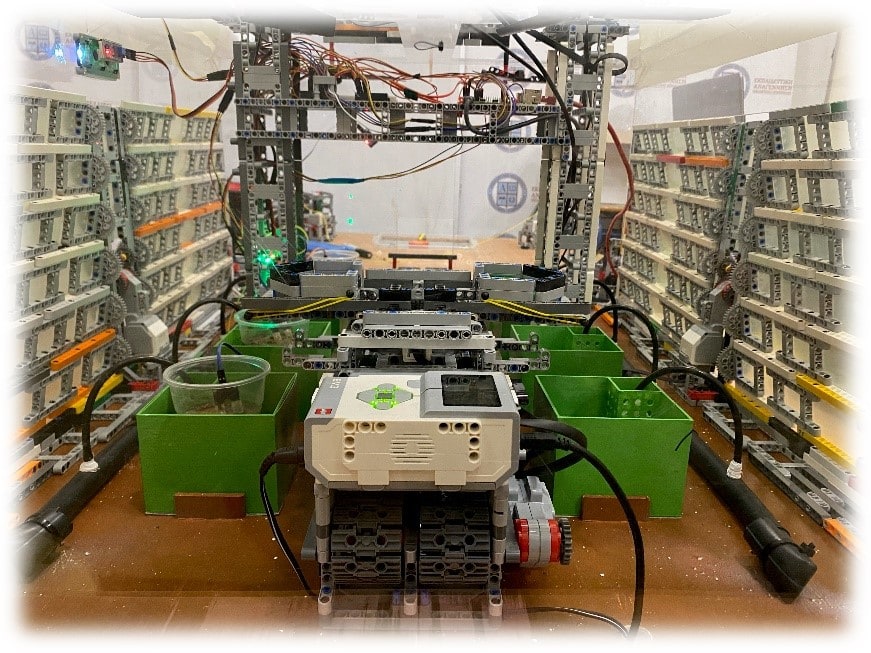

Flying Turbine (3D model)

The kettle

Flying Turbine

Wind turbine brackets

Greenhouse

Note: Some parts of the construction differ due to the Portfolio being issued before the Project was at its final state.

FINANCIAL PART

Detailed Business Plan

Budget of the greenhouse construction (cost/acre)

- Metal core

- Special cover

- Soil treatment

- Irrigation

- Shading system

- Cooling system

- Heating system

- Planting reception materials

- Water tanks

- Fertilizer tanks

- Storage

- Control rooms

From the electricity that flying windmill produces, the ¾ will be sold out to a provider and the rest of the electricity will be consumed to the greenhouse in order to run its functions.

Hardware Analysis

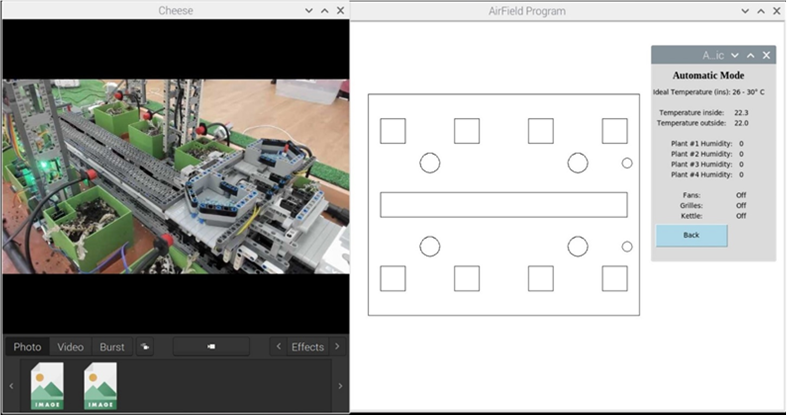

The Program

For the program of the Project, we used:

- Raspberry Pi 4 – VNC Viewer (Python)

- Lego Mindstorms

- PyCharm (Python)

Libraries that we have used:

import serial -> serial communication between other devices and Raspberry Pi

import EV3BT -> communication between Raspberry Pi and EV3 through Bluetooth

import RPi.GPIO as GPIO àcommunication with devices through wire

import dht11 àprogramoftemperatureandhumidity sensors

import time -> command of time

import datetime -> use of current date and time

import drivers -> for the lcd monitor

import turtle -> design of the app

from tkinter import* -> program for the app

from tkinter import messagebox -> create notification for the app

The program of the Project consists of 5 different subprograms. The 3 programs concern the greenhouse, and the others are for the flying windmill. Regarding the greenhouse, 1 program in use is in the Raspberry Pi and the other 2 are EV3 programs. Raspberry Pi communicates with both EV3 programs. The fists EV3 program is used for the regulation of the temperature inside the greenhouse and the other for fertilizer application.

1) The program of the conveyor belt:

The basic logic of the program is the exchange of messages between the raspberry pi and the EV3. More specifically the program of raspberry pi works as “the brain”, and the EV3 executes the commands depending on the messages which the raspberry sends. The humidity sensors constantly take measures from the plants, and they return 1(True) if they detect humidity or 0(False) if they do not. When a sensor detects less humidity than normal, raspberry pi sends a message in the EV3 with the unique number corresponding to the plant with the unregular humidity. Then the EV3 program, calculates the distance the robot has from the plant and executes suitable commands.

s_1 = EV3BT.encodeMessage(EV3BT.MessageType.Numeric, 'number', 2) #lipasma

EV3_1.write(s_1)

print(EV3BT.printMessage(s_1))

time.sleep(2)

Communication code of Raspberry pi

Communication code of EV3

2) The program of temperature regulation:

The temperature sensors are constantly taking measures inside and outside the greenhouse. The ideal temperature for our plants is between 20-25 °C. If the temperature inside the greenhouse is under 20 °C the kettle operates automatically until the temperature turns back to the ideal conditions. In case the temperature is increased more than the setpoint, the system operates the fans for the temperature to become ideal again for the plants. Despite all these, there is a case when the temperature outside the greenhouse is the temperature we want to adjust inside the greenhouse. In this case, the windows are opened automatically, letting the temperature being adjusted by itself in order to save as much energy as possible. Again, in this program the raspberry pi detects the temperature through the sensors, the EV3 receives the messages and operates the motor that is needed in each case.

Analyzation for the App Development

The app that we have created on the website is separated into 2 categories: (a) the investor and (b) the administrator.

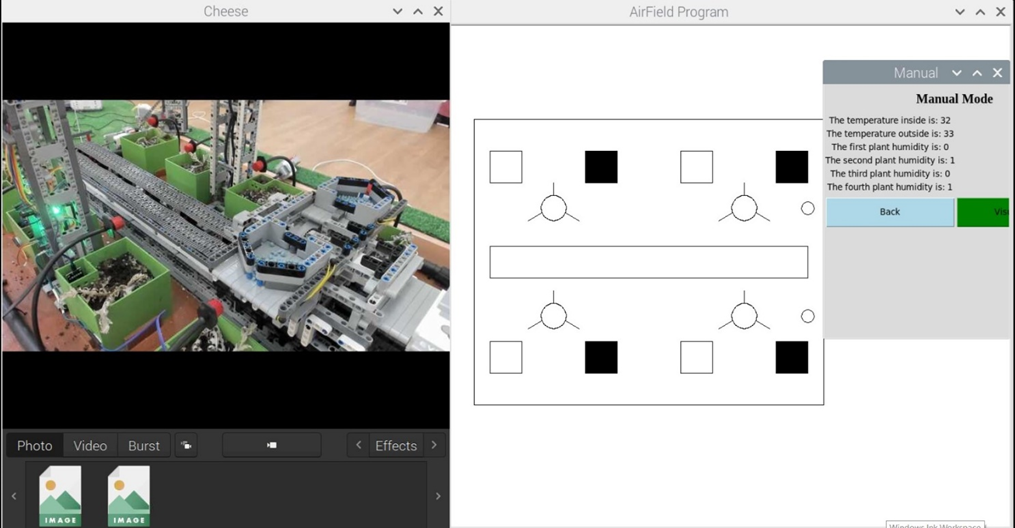

Administrator

We have connected the administrator mode with the VNC, which is the platform that we have programmed the code both for the flying windmill and greenhouse. The administrator mode is also separated into 2 categories: one is for the flying windmill and the second one is for the greenhouse. Both of them are separated into 2 other categories: the automatic and the manual mode. In the automatic mode, the potential administrator can see live measured values and the system’s condition. In the manual mode, the administrator can provide the required input values in order to direct the project from a distance.

Investor

The investor mode is also separated into 2 other categories. The first one is this of budget, where the user can provide a budget and based on an algorithm that we have created, the site shows him a plethora of choices to invest with detail on how many flying windmills, how many greenhouses, the location, the profits etc. The second one is the opposite, where the user can apply the standards he wants and based on an algorithm too, the site calculates the total budget of what he has applied.